Design and Order: The customer specifies the desired design for the ceramic tiles. This can be an existing pattern or a custom-designed pattern.

Preparation of Clay: The clay is prepared by cleaning and kneading it to ensure it is free from impurities and has the right consistency.

Shaping: The clay is shaped by hand into the desired form. This can be done by rolling, cutting, or pressing.

Decoration: The design is applied to the shaped tiles. This can be done by painting, stamping, or carving the design into the wet clay.

Drying: The tiles are dried to remove excess water. This must be done slowly to avoid cracks.

First Firing: The tiles are heated in a Hoffmann kiln to a low temperature. This process, known as “biscuit firing”, hardens the tiles and prepares them for glazing.

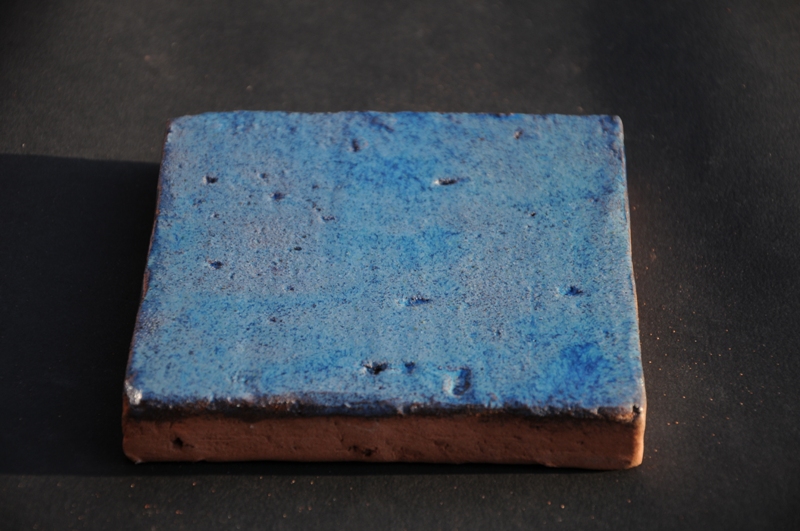

Glazing: The tiles are glazed. The glaze can have different colors and textures, depending on the customer’s wishes.

Second Firing: The tiles are put back into the kiln, this time at a higher temperature. This process, known as “glaze firing”, melts the glaze and binds it to the tile.

Cooling and Packaging: After cooling, the tiles are inspected, cleaned, and packaged for shipping.