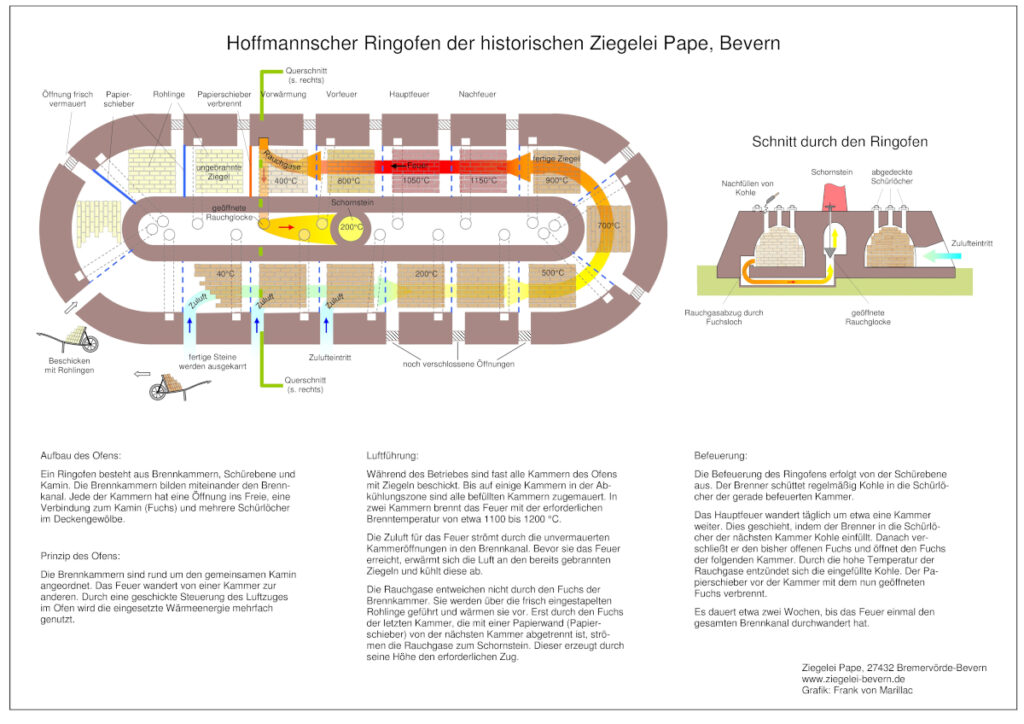

A Hoffmann kiln is a type of continuous kiln that was patented in 1858 by the German inventor Friedrich Eduard Hoffmann. This type of kiln revolutionized brick production in the 20th century by:

Continuous operation: Unlike the previously common chamber kilns, which had to be refilled and reheated after each firing, the ring kiln allowed for continuous operation. The fire moved around the oval in about one to two weeks.

Energy efficiency: By ventilating the chambers, the fired bricks heat the air supply for the fire, which in turn cools them down faster, while the hot exhaust gases dry and preheat the blanks.

Consistent quality: The continuous firing provided a consistent quality of bricks for the first time.

Increase in production: The ring kiln enabled an unprecedented increase in brick production

The Hoffmann kiln could be in continuous operation throughout the season. The fire burned incessantly and always moved in a circle from firing chamber to firing chamber. In five of them, new brick blanks were filled in and finished bricks were taken out, another five were preheated by waste heat (which led to a fuel saving of up to 60%), in the next five chambers the bricks were fired at 750 – 1000°C and then cooled in the last five sections.

These innovations led to the image of houses changing from gray (reed and straw roof, bush, wood, clay walls) to red (roof tiles, brick house, less fire hazard).

During the firing process, new fuel was added every 10-20 minutes through the firing flaps from above between the brick stacks. This was the task of the firing master, who also supervised the entire firing process in shift operation. The brick blanks were under fire for up to 52 hours, so it took about 10 days for the fire to have traveled through the entire oven once.

It is also worth noting that the Hoffmann ring kiln was adapted in the lime and gypsum industry (English patent of 1868, Humphrey Chamberlain), although all similar kilns continued to be called Hoffmann kilns. Today, there are still about 100 ring kilns in older ceramic factories in Poland.